Knowing All Aspects of a Properly Installed Roofing System

In this article, we are going to cover all the aspects of a properly installed roofing system. We like to refer to your roof as a roofing system because a roofing system is what protects your home, and a roof is just a generic term for the top of your house.

We will be going over the following components of your roofing system:

- Solid Sheathing

- Proper Underlayment

- Valley Liners

- Flashing

- Starter Shingles

- Field Shingles

- Ventilation

- Ridge Cap Shingles

While discussing the necessary components of your roofing system, we will also touch upon why the components are necessary in relation to both manufacturer specifications and local building regulations.

Sheathing:

The first component of your properly installed roofing system is a solidly sheathed surface. The sheathing is what is attached to your rafters that facilitates the installation of underlayment and shingles. Most roofs will utilize dimensional lumber or structural panels like OSB or Plywood. Current building code R 905.2.1 Sheathing Requirements mandates that structural panel sheathing must be a minimum of five eighths of an inch thick.

Due to the amount of force sealing shingles can exert on the roof sheathing, most shingle manufacturers would prefer to see one by lumber ripped to six inches instead of the traditional twelve inch width. Verifying that sheathing is properly secured during a roof replacement is paramount to the overall outcome of the completed roofing system by ensuring that there is a suitable nailable surface for installing underlayment and shingles.

Underlayment:

The next component of your roofing system is the roofing underlayment. Traditionally, 15 pound felt paper was used as underlayment; however, science and technology has moved us past the dark ages. Manufacturers now produce and prefer the use of synthetic underlayment in their roofing systems. Code R 904.1 states that you must adhere to all manufacturer specifications, so underlayment is required by both manufacturer specifications and code. When applying the synthetic underlayment, it is important that the underlayment overlaps your drip edge on the eaves and is secured under the drip edge on the rakes of your roof.

In certain situations, application of double underlayment is required. Typically, any roofing plane is under a certain slope or pitch requires double underlayment. Roof planes with slopes or pitch of 2 in 12 units up to 4 in 12 units require application of double underlayment.

Removal of existing felt and underlayment during a roof replacement is critical to the integrity of the new roofing system. Without removing all existing felt and underlayment, proper inspection of the roof sheathing is not possible.

Valley Liner (Ice and Water):

Valley liners are required by both manufacturer specifications and local building codes. Code R 905.8.2 requires one of three types of valley liners; however, we will focus on installing Ice and Water Barrier. This is due to that being the most common type of liner required by numerous shingle manufacturers. Ice and Water Barrier is a self-adhering membrane that creates an impervious water barrier in the valleys of your home. The Owens Corning Weather Lok Ice and Water Membrane will keep your home dry while satisfying local building regulations and manufacturer specifications.

Flashing:

When completing a roof replacement, it is required to replace all flashings and edgings. Code R 907.5 addresses reinstallation of materials of your roofing system, including items like drip edge, step flashings, and counter flashings. Be sure that all components of your roofing system are being addressed.

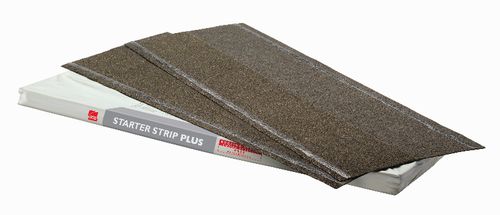

Starter Shingles:

Use of a dedicated starter shingle is required by the vast majority of all asphalt shingle manufacturers, and code R 904.1 dictates the adherence to manufacturer installation instructions. Utilizing a cut shingle as a starter shingle is an antiquated practice and runs the risk of violating the terms of the particular shingle manufacturer’s warranty.

As you see on this Owens Corning Starter Strip Plus Starter Shingle, there are specific seal strips that create a chemical bond of the starter shingle and subsequent field shingle. The bonding of the starter shingle and field shingle are what gives your roofing system added protection against high winds during times of storming weather. Starter shingles are required to be installed along both the eaves and rakes to achieve maximum wind resistance.

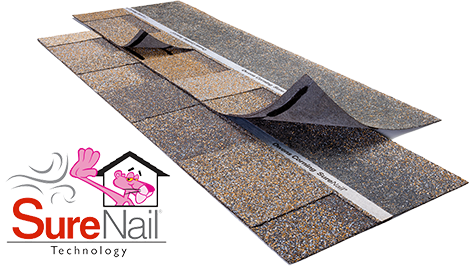

Field Shingles:

Field shingles are to be installed in accordance with manufacturer specifications; and depending on your roof’s slope, may need additional steps for proper installations. Code R 905.2.2 addresses installation requirements pertaining to different slopes. The Owens Corning Duration Series Shingle is an amazing shingle that takes the guesswork out of installation. The patented surenail strip found on the Duration Series Shingle provides an almost full 1” nail bed and a third layer of laminate protection. This means less installation errors and higher wind resistance.

Ventilation:

A properly installed roofing system is utilizing both intake and outtake attic ventilation. There are various types of intake vents that should already be installed on your home, and in this article we are mainly focusing on outtake ventilation. There are two primary types of outtake ventilation: static box vents and ridge vent. Both ventilation systems follow the 1 : 300 rule in which a home needs 1 sq ft of ventilation for every 300 sq ft of attic floor space. A general rule of thumb for static box vents is one vent for every 3 – 4 square of roofing material whereas a home would need 20 linear feet of ridge vent for every 10 square of roofing material: making ridge vent a non-option for most stick-built hip roofs. Proper ventilation is required by the vast majority of material manufacturers, so make sure that your roofing system is vented properly. Keep in mind that Code R 907.1 requires that existing vents be replaced when completing a roof replacement.

Ridge Cap (Hip and Ridge Shingles):

The final component of your roofing system is the Ridge Cap. Ridge Cap specific to your roofing system should be selected and installed in accordance with the manufacturer specifications. The practice of cutting ridge caps from three tab shingles or other shingles is antiquated in practice when installing a laminated shingle like the Owens Corning Duration shingle. The Ridge Cap has been designed to perform to the limits of your roofing system. Your roofing system is only as good as its weakest component, so utilizing the proper ridge cap is critical to the functionality of your roofing system. Owens Corning Proedge is specifically designed to finish your roof while ensuring industry leading wind resistance.

As you can see, there is a lot more to your roof than just shingles. A properly installed roofing system is crucial to the life of your home. Luckily, you can choose a competent and certified contractor to help you throughout the entire project. The peace of mind that comes with working with a competent and certified contractor is invaluable when the health of your home is on the line. Choose wisely and keep in mind both manufacturer specifications and local building regulations. If you are having an Owens Corning roofing system installed, then remember you need to install the field shingles plus three other Owens Corning components for your warranty to be valid. We hope this article has helped you gain a better understanding of your roofing system, and I wish you the best of luck with your project.

We dedicate ourselves to providing homeowners peace of mind by offering complimentary inspections. With years of roofing experience, we take pride in our ability to identify improperly installed roofing systems and prevent long term damage before it is too late!

Contact us today to schedule a complimentary inspection!